Supplier Handbook

With our partner companies we are on equal level in planning and processing. This supplier handbook is intended to contribute to smooth processes between suppliers and MEYER TURKU and to minimize costs.

The complete supplier handbook is currently being prepared and will be published shortly.

Here you will find important information and links to work safely and efficiently at the site.

GOOD TO KNOW - HIGHLIGHTS

Employee registration & start of work

Companies

Before MEYER TURKU can finalize a contract with a supplier for work within the shipyard (e.g., design, installation), the responsible purchasing manager must request necessary documents from the supplier. Each supplier with a contractual agreement must ensure that their subcontractors comply with the same requirements. Subcontractors must provide the required documents and submit a completed subcontractor company information form to the permit office before beginning any work.

Individuals

To receive access permits for the shipyard, an access permit application must be completed for each worker through the PDC system (see Person Data Card instructions). An access permit application is also required whenever there is a change in contract, project, or employer. When an employment relationship ends, the employer must promptly inform the permit office. Additionally, if the company changes, the ID card must be replaced with a new one.

The "Before starting work" describes the steps to be taken when applying and how to handle the shipyard pass. If detailed information, including data entry within the form, is required, we would ask you to select the instructions for a short-term or permanent ID card directly.

More information on signing staff in and out can be found in the access to the shipyard section.

Required HSE Trainings

To maintain the highest standards in health, safety, and environmental (HSE) practices, comprehensive training programs are essential. At MEYER TURKU, it is mandatory for everyone entering the shipyard to possess an Occupational safety card and complete an HSE orientation at the Permit Office prior to entry.

Additionally, we require the following trainings according to occupation:

- Hot work pass card

- Electrical safety card SFS 6002

- Emergency first aid card

- Forklift license

- Personal lift operator

- Crane operator

Photography-prohibition and -permission

There is a general ban on photography and filming with smartphones, cameras and similar devices on the shipyard premises and on new buildings/ships. This also applies to sharing any photos taken within the shipyard area or of ships under construction.

Photography is only permitted in designated areas within the shipyard. These areas include:

- The end of the outfitting dock, facing the ship being outfitted.

- The fire drill area, which can be accessed by going past buildings P84 and P83.

In both locations, the direction of photography should be towards the bow of the ship.

Exceptions for taking photos or videos must be requested and approved by the respective communications specialist of the MEYER TURKU’s communications department.

In accordance with the MEYER Group's information protection policies, photographs must be protected from unauthorized or unlawful access by third parties. They can only be shared with trusted individuals when necessary for their work-related tasks. These photos are strictly for operational use. Any further distribution is prohibited. The MEYER Group reserves the right to demand the deletion of these photos at any time, unless a statutory retention period applies.

Violations of this prohibition by employees of our suppliers as well as their sub-suppliers will be punished with a contractual penalty for the partner companies and/or a shipyard ban for the respective employee.

Smoking, alcohol and drugs prohibition

Smoking is permitted only in designated smoking areas, both on board and within the shipyard premises.

It is prohibited to bring alcoholic beverages, drugs and other addictive substances to the site or to consume them there. It is prohibited to enter the yard under the influence of alcohol or otherwise intoxicated state. Our goal is to maintain a substance-free work community.

MEYER TURKU promotes complete non-usage of drugs and moderate alcohol consumption during free time by providing information on the harms of substance use.

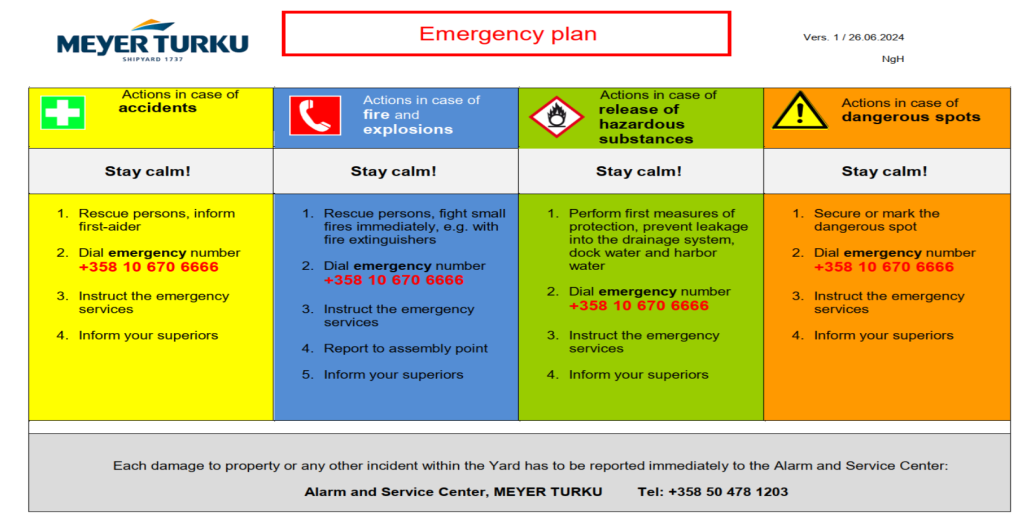

Emergency- & Alarmplan

The rescue plan, governed by the Rescue Act (379/2011) and Government Decree on Rescue Services (407/2011), provides instructions on responding to accidents and emergencies. All departments have guidelines for ship and building fire emergencies, including meeting points. Emergency calls are made by dialing 010 670 6666, and the main gate notifies the shipyard's fire brigade.

Any deviations (accidents, Near Misses, fires, releases of hazardous substances and dangerous places) shall be reported to MEYER TURKU’s HSE-department through Meyer Eye at: https://eye.meyerturku.fi/.

Tidiness and Order

Building a ship is a complex process that requires careful planning and execution. One of the key aspects in shipbuilding is maintaining cleanliness to ensure safety and fire prevention. Maintaining cleanliness and orderliness is crucial for safety and fire prevention. Clean and organized spaces facilitate movement and evacuation during emergencies, therefore MEYER TURKU instructs everyone working at the shipyard to clean their workspace daily.

The corridors, stairs and other escape routes must be kept clear from obstacles and construction material to ensure efficient and safe evacuation.

Additionally, cleanliness must be maintained daily because the removal of excessive fire load reduces the risk of accidents and starts of fire. Litter and objects scattered in random places can cause tripping and falling, which is particularly dangerous in confined spaces where limited room and motion instability can increase the risk of injury.

Regular cleaning, waste management, safety training, hot work pass card training and effective fire safety systems ensure safe operation. Keeping the ship clean during the construction phase is a good practice to ensure the safety of the ship.

Cleanliness reduces the risk of accidents and promotes efficient operation and emergency preparedness.

- A well-organised workspace minimises potential fire hazards.

- More working space available.

- Reduced likelihood of tripping and injury risks from falling objects.

- Less time spent searching for tools and materials.

- Systematic environments make assembly processes more efficient.

- Overall production is significantly improved.

- A clean workplace contributes to the atmosphere by reducing irritation and prevents disagreements between colleagues.

- A clean and tidy space is more pleasant to work in, making daily tasks easier.

Changing rooms, lockers, washrooms and social rooms

Suppliers must provide adequate facilities for their employees according to the Occupational Safety Health Act (23.8.2002/738). MEYER TURKU leases social facilities to suppliers and subcontractors when possible. Leasing can be inquired from the Permit Office at Turku.lupatoimisto@meyerturku.fi.

Leasing or rental of containers for social facilities and location of facilities must be agreed upon with MT's maintenance department, and ICT connections with the data administration department.

There are also two canteens located in the shipyard. For more information, please visit the canteen’s website here.

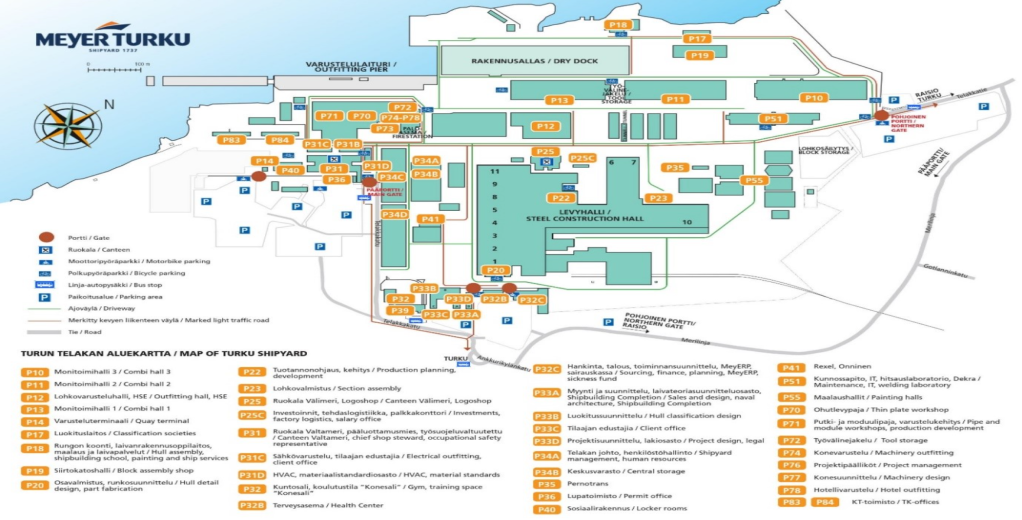

Parking Areas, Internal Traffic and Public Transport

Several parking areas are available outside the shipyard gates. Rescue and driving lanes must remain clear, therefore parking in these areas is prohibited. The City of Turku's parking enforcement regularly monitors parking on the streets leading to the shipyard and within the shipyard's parking areas. Access through the revolving gates requires an ID card, which is personal and must not be lent to others. If you do not have an ID card or if it does not work, access is possible through the main gate or the north gate by registering with the guard.

Driving instructions to the gate.

Some parking spots are reserved for visitors outside the area, near the gates. Visitors should stop their cars in the waiting area along the street leading to the gate and register at the gate service window, where the guard will assist with parking-related questions.

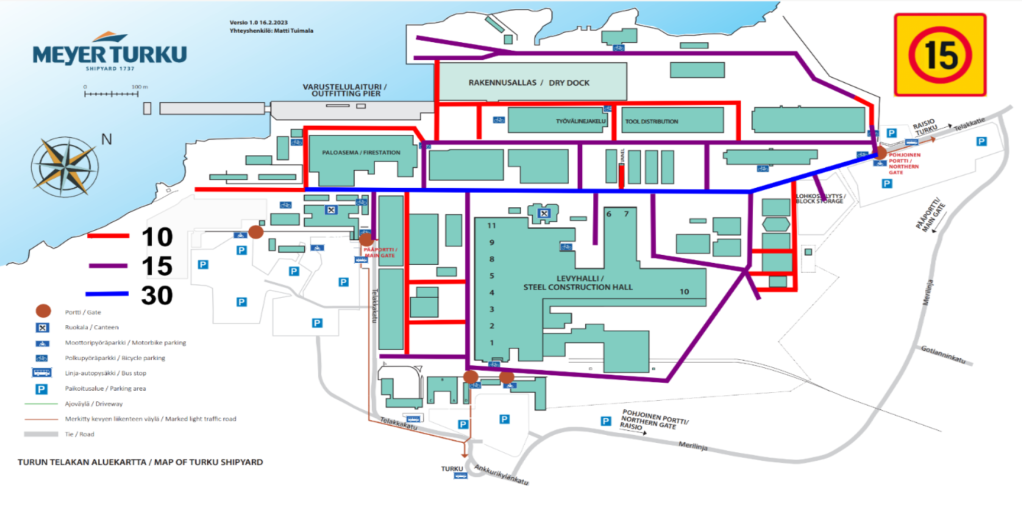

Driving inside the shipyard is only allowed in special cases, typically for temporary activities such as delivering or picking up goods. Temporary driving permits can be obtained at the gate. Permanent driving permits are managed by the traffic steering group and permits shall be applied according to the other instructions.

Mobile phone use while driving is prohibited; the vehicle must be pulled over in a safe place or drivers must use a hands-free device. Adhere to the speed limits within the shipyard area according to the map below. These limits apply to all vehicles, including bicycles. Driving speed must be reduced further in busy areas and where visibility is limited. Use of electric scooters are prohibited during working hours.

There are plenty of public transportation routes offered by Föli. For more detailed information of the bus stops, please, see the map of Turku Shipyard. Please, have a look at Turku Map Service, as well.

Personal protective equipment (PPE)

MEYER TURKU has outlined the mandatory personal protective equipment (PPE) in production areas as follows: safety shoes, safety helmet, safety glasses, high visibility protective clothes and a functional flashlight. Additional protection as required by the work, e.g. welding equipment and fall protection. Detailed task specific instructions on PPE usage can be provided on request.

Employers must provide suitable PPE and ensure proper instruction on its use. Everyone, especially those in a supervisory role, bears the responsibility to address inadequate protective gear.

All employees and subcontractors must wear the mandatory PPE when entering and working at the shipyard. Employees engaged in network cooperation at MEYER TURKU are tasked with ensuring that supplier companies adhere to the shipyard's safety protocols. Line managers monitor the proper use of task-specific protective equipment. It is mandatory for employees to wear the necessary protective gear for their assigned tasks.

If you have any questions, please contact the MEYER TURKU safety department.

Employees of the supplier

The responsibility of the personnel remains with the supplier.

Supplier may only employ sufficiently qualified personnel in compliance with local laws and regulations. They must particularly adhere to legal provisions against illegal employment while fulfilling their contractual duties. Young people under the age of 18 may enter the shipyard only for the purpose of apprenticeship or with prior approval from appointed persons, such as the safety manager or security manager of MEYER TURKU.

Upon Meyer Turku’s request, suppliers must submit appropriate qualification certificates for their personnel. Depending on the risk level of the services to be provided, health, safety, and environmental protection (HSE) certificates must be submitted. Safety protocols must be integrated throughout the supplier chain, with all employees receiving comprehensive training on workplace safety matters. The rules and guidelines of MEYER TURKU apply fully to sub-suppliers. The supplier must instruct their sub-suppliers in writing to ensure compliance before use.

Sub-suppliers are not contractual partners of MEYER TURKU.

MEYER TURKU reserves the right to reject any sub-supplier at any time for objective reasons to protect legitimate interests.

Claiming (Damage, Defect, Delay)

Claims against MERYER TURKU (incoming claims) must be reported within three working days. For this purpose it is mandatory that you send the claim by e-mail to the technical responsible person or your contact person in procurement.

Please note that failure to comply with these deadline requirements will usually result in rejection of the claim.

Notification of delivery and delivery of goods

Deliveries are made according to the order to Meyer Turku.

Delivery locations:

- Main Gate: Telakkakatu 1, 20240 Turku

Northern Gate: Telakkatie 1, 20240 Turku

Warehouse opening hours:

- Open Monday–Friday: 7–11 a.m. and 11:45 a.m.–3 p.m.

No deliveries between 11–11:45 a.m.

DAP Deliveries

- 1. Notification and Documents:

- Follow the instructions that you have received from us with our purchase order (PO) and notify us of your delivery 48 hours in advance.

- Fill in and send "Delivery notification Meyer Turku 2022.pdf" with packing list and AWB to prealerts@meyerturku.fi.

- 2. EORI and VAT Numbers:

EORI: FI0772017-4

VAT: FI07720174 - 3. Specific Requirements:

Provide technical drawings, attachment points, center of gravity, weight, and crane needs if applicable.

FCA deliveries

- 1. Instructions

- Follow the instructions that you have received from us with our purchase order (PO)

- Verify correct delivery address from the PO as it may differ

- Include contact person's full name, telephone number, and e-mail address on delivery documents.

- 2. EORI and VAT Numbers:

EORI: FI0772017-4

VAT: FI07720174 - 3. To book the transportation please send the following information to meyerturku@wiima.fi

- Collection address and contact details (full name, telephone number, and e-mail address)

- Loading hours and if special equipment is needed (side load, curtain trailer, backtail etc.)

- Quantity of pallets

- Dimensions & weight for each pallet

- Information if the shipment is stackable / required loading meters

- If the shipment includes any hazardous or classified materials, please send Shipper's Declaration for Dangerous Goods (DGD) according to international rules for transport of dangerous goods (IMDG, IATA DGR) and please attach Safety Data Sheet (SDS)

- If the goods are from 3rdcountries or of NON-EU origin, owner of the goods as an exporter is responsible for submitting an export declaration or a bonded goods transit document T1.

- Delivery notification

- Delivery Instructions for FCA deliveries

- Guidelines of delivery

Screening of suppliers before cooperation

Modern shipbuilding relies heavily on teamwork, and our success depends on our suppliers. We aim to know our partners well in advance to ensure smooth cooperation from the outset. Our Supplier Management department will first request general information about your company, along with relevant certificates and documents for your field of work. Once approved, you will undergo a qualification test process with your future contacts at Meyer Turku. Although this initial exchange of information can be time-consuming, our partners are typically rewarded with long-term cooperation opportunities.

Order confirmation

A valid order confirmation from the supplier is necessary to finalize the order. The purchaser must ensure the order confirmation accurately reflects the order details. Discrepancies must be addressed with the supplier.

Please, send order confirmations by e-mail to your responsible purchaser.

Invoicing

Meyer Turku vastaanottaa ainoastaan sähköisiä laskuja. Laskuihin liittyvät kyselyt lähetetään jatkossa erilliseen osoitteeseen invoice.clearing@meyerturku.fi

Meyer Turku

Electronic Invoices

E-invoice address: 0037077201741

Operator: OpusCapita (E204503)

Pdf-invoices by email: invoice@meyerturku.fi

Inquiries related to purchase invoices: invoice.clearing@meyerturku.fi

In case you notice any errors in our order documents issued 4.11.2024 or later, we kindly ask you to inform the purchaser about it.

Invoice Submission Requirements:

Format:

- Send invoices in PDF format.

- Attachments must be included in a single PDF file, with the invoice page first.

- One email can contain multiple PDFs.

- Only send invoices and credit notes to the specified email; other correspondence will be deleted.

Invoice Content (Mandatory Information):

- Purchase order number in reference of all invoices (for goods orders).

- Alternatively, the contract number or the name of the purchaser/reviewer.

- Delivery address of goods/services or any other agreed alignment information.

- Time sheet/readiness report as agreed.

- Invoices must meet applicable legal requirements.

- Invoices sent to the wrong address or with incomplete information will be returned.

- Late payments due to incorrect submission are not the company's responsibility.